The Process

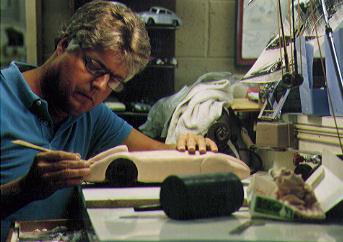

The next step is the work of a

professional mold maker, who carefully produces a latex mold of the clay and wax sculpture,

which is then covered by a heavier layer of plastic or fiberglass. A new wax model is

produced in this mold which Gamble can then finish and perfect.

|

The process

begins with a type of plasticized clay in which a mold is created in the basic shape of

the sculptures. To this rudimentary form a special wax is added, blended in its viscosity

to hold up in the wide scope of seasonal temperatures common to the Arizona region where

Mr. Gamble lives and works. It is to this wax layer that Gamble adds the detail of his

piece.

|

And then it's off to the

foundry for the casting in bronze, yielding a series of sculptures which comprise an

"edition." These sculptures are then finished or "chased," a tedious

process of fine tuning the cast pieces, filling in little pits and filing off any seams

and other marks left by the mold. And finally they are polished to enhance the true color

of the bronze. And then it's off to the

foundry for the casting in bronze, yielding a series of sculptures which comprise an

"edition." These sculptures are then finished or "chased," a tedious

process of fine tuning the cast pieces, filling in little pits and filing off any seams

and other marks left by the mold. And finally they are polished to enhance the true color

of the bronze.

|